Manufacturer Name |

N/A AW-Lake Company |

Type |

N/A Inline Proces Sensor |

Connection Type |

N/A Sanitary Clamp |

Connection Size |

N/A 3" |

Output |

N/A 4-20 mA |

Power Consumption |

N/A 0.45 W |

Supply Voltage |

N/A 15 to 24 V |

Standard |

N/A 3-A Sanitary Standard, #46 |

Housing |

N/A NEMA 6 / IP67 enclosure |

Optical Lens |

N/A Sapphire |

Lens Seal |

N/A FDA approved silicone rubber |

Temperature Rating [Min] - Constant |

N/A 32 ºF0 ºC |

Temperature Rating [Max] - Constant |

N/A 212 ºF100 ºC |

Temperature Rating [Min] - Intermittent |

N/A 32 ºF0 ºC |

Temperature Rating [Max] - Intermittent |

N/A 300 ºF149 ºC |

Body & Connector |

N/A 316L stainless steel |

Process Port Type |

N/A 3" SANITARY CLAMP |

|

N/A

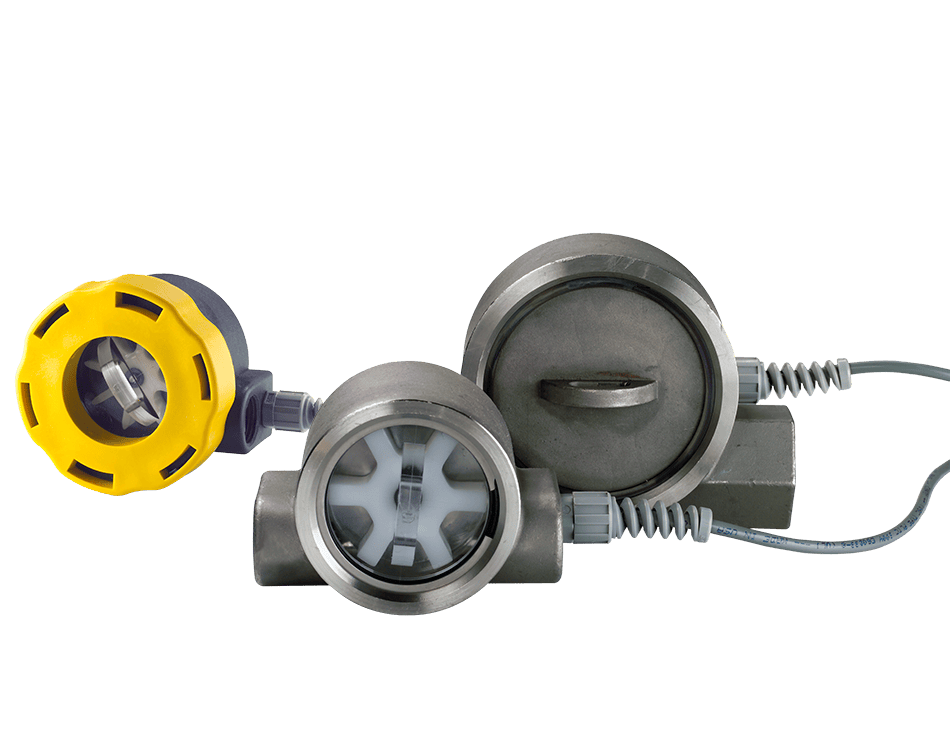

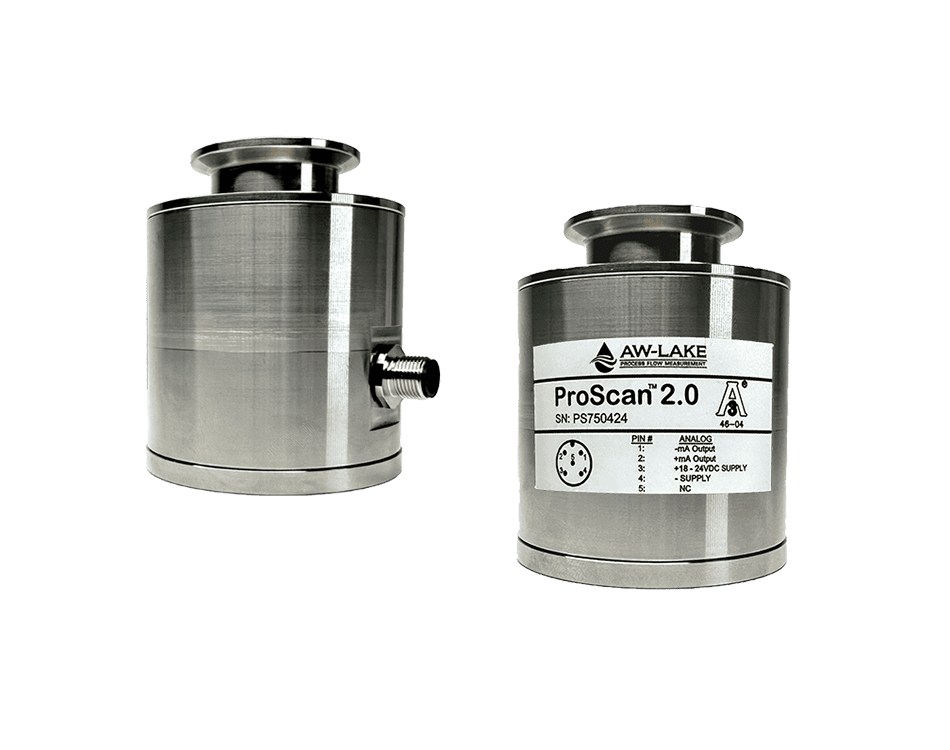

Utilizing advanced optical and microprocessor technology, ProScan produces a linearized

4-20 mA output that can be tailored to a wide range of applications. The sensor attaches

directly to the process line and allows real-time, in-line analysis of fluid streams. The

sapphire lens and 316 stainless steel construction will withstand the high temperatures, rapid

temperature fluctuations and chemical agents typical in food processes. The simple design

allows plant personnel to install, tune and maintain it with ease. |

|

N/A The ProScan signal can be used to switch valves and direct the liquid stream to the filler, recirculate it or divert to drain. ProScan is also a valuable tool to control CIP pre rinse cycles and maximize product recovery. The simple NIR sensor helps processors recover as much product as possible before initiating cleaning and helps to ensure expensive chemicals are added at the appropriate time. In addition, ProScan can act as an excellent monitor of BOD loading on waste lines. From receiving lines and pasteurizing lines to filling lines and waste lines, ProScan offers an economical solution to your process control needs. |

|

N/A

Highly Accurate Non-Intrusive Monitoring Improved Automation 3-A Sanitary |

Quantity Available |

N/A {Unknown} |

*1-5 Pieces |

N/A {Unknown} |

*6-10 Pieces |

N/A {Unknown} |

Std Lead Time |

N/A {Unknown} |