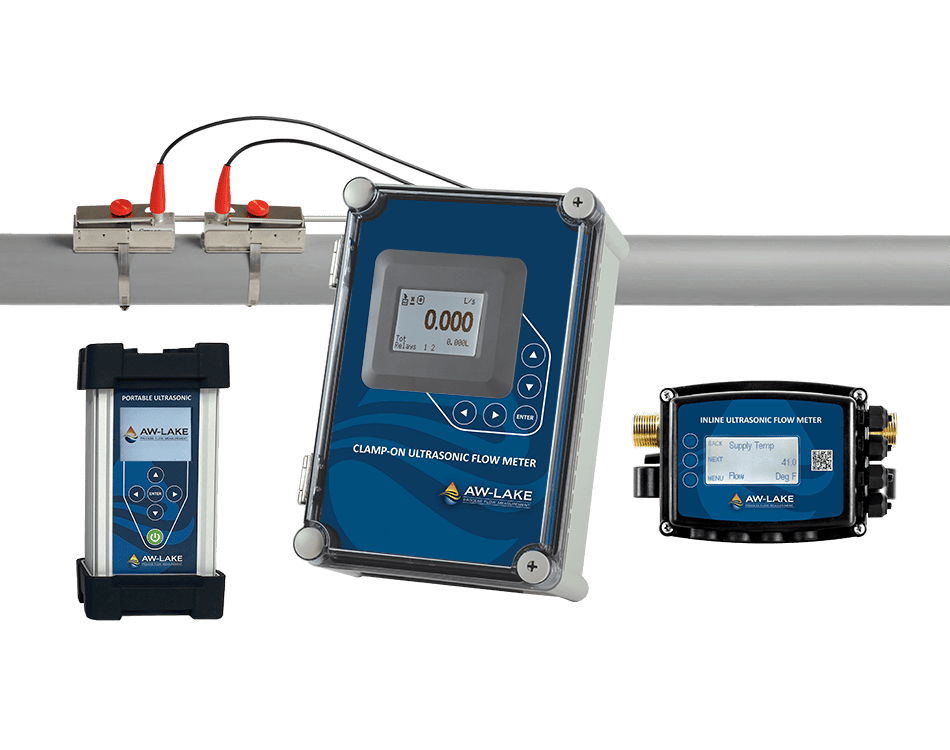

Using the Transit Time measurement principle, the CUTT Clamp-On Ultrasonic Flow Meter fastens on the outside of vertical or horizontal pipes ranging in size from ½” through 48”. Housed in a water- and dust-tight NEMA4X polycarbonate enclosure, the Clamp-On Ultrasonic Flow Meters offer Isolated 4-20 mA and 0-5 V analog output. The non-intrusive flow measurement allows measurement of the most “corrosive liquids” that would damage standard flow meters. Clamp-on transducers can accommodate all common pipe materials at diameters from 0.5” to 48” and withstand temperatures from -40°F to 300°F. The meter comes with free datalogging software for data display, manipulation, analysis, and exporting.

Applications include:

- Food processing

- Chemical processing plants

- Oil refineries

Manufacturer Name |

N/A AW-Lake Company |

Type |

N/A Ultrasonic Flow Meter |

Style |

N/A Clamp-on |

Power Input |

N/A 100-240VAC, 50/60Hz, 10VA Max. |

Enclosure & Electronics Protection |

N/A NEMA4X (IP66) polycarbonate enclosure |

Enclosure Temperature Rating |

N/A -5 to 140 ºF-20 to 60 ºC |

Intrinsic Safety Rating |

N/A QTY 2 ISB Intrinsic Safety Barriers for transducer installation in Class 1 Div 1, Groups C, D; Class 2, Groups E, F, G; Class 3; Type 4 |

Transducers |

N/A SE16A pair, clamp-on for 0.5" to 4" (15 mm to 100 mm) pipes, BNC connectors and IP65 rating |

Transducer Mounting Hardware |

N/A TMK-A1 – Includes stainless track mount with built-in ruler, mounting clamps, and silicone coupling compound. Standard option for SE16A transducer pair. |

Cables & Connections |

N/A 100 ft/30 m pair triaxial with BNC connectors and seal jackets |

Serial Communications |

N/A Modbus® RTU via RS-485 or HART (field selectable) |

Control Relays |

N/A 4 Extra Relays (6 total), rated 5 amp SPDT, programmable |

Measuring Accuracy |

N/A ±1.0% of reading from 1.5 to 40 ft/sec (0.5 to 12.0 m/sec) and ±0.015 ft/sec (±0.0046 m/sec) for velocity below 1.5 ft/sec (0.46 m/sec). |

Repeatability & Linearity |

N/A ±0.25% |

Flow Measuring Range |

N/A 0.07 to 40 ft/s0.02 to 12 m/s |

Pipe Diameter |

N/A SE16A: 0.5" to 4" (15 mm to 100 mm) SE16B: 2" to 48" (50 mm to 1200 mm) |

Pipe Materials |

N/A Any metal or plastic sonic conducting materials, including carbon steel, stainless steel, ductile iron, concrete lined ductile iron, cast iron, PVC, HDPE, PVDF, fiberglass, copper, brass, aluminum, and pipes with bonded liners, including epoxy, rubber, and PTFE. |

Operating Frequency |

N/A SE16A: 2.56 MHz SE16B: 1.28 MHz |

Transducer - Operating Temperature Range |

N/A -40 to 300 ºF-40 to 150 ºC |

Electronics - Operating Temperature Range |

N/A -5 to 140 ºF-20 to 60 ºC |

Analog Output |

N/A Isolated 4-20mA/0-5V, 1000 ohm load max., programmable offset |

Hazardous Area Certifications |

N/A Non-Incendive for Class I Division 2, Groups A,B,C,D Optional: Intrinsically safe for Class I Division 1, Groups A,B,C,D |

Approximate Shipping Weight |

N/A 12 lb5.5 kg |

A |

N/A 10.94 in278 mm |

B |

N/A 7.4 in188 mm |

C |

N/A 5.12 in130 mm |

D |

N/A 10 in254 mm |

E |

N/A 6.46 in164 mm |

|

N/A

|

|

N/A

Non-Contacting Flow Measurement User-Friendly Operating System Industrial Automation Protocols Wide Range of Applications Safe in Wet Locations |

Quantity Available |

N/A {Unknown} |

*1-5 Pieces |

N/A {Unknown} |

*6-10 Pieces |

N/A {Unknown} |

Std Lead Time |

N/A {Unknown} |