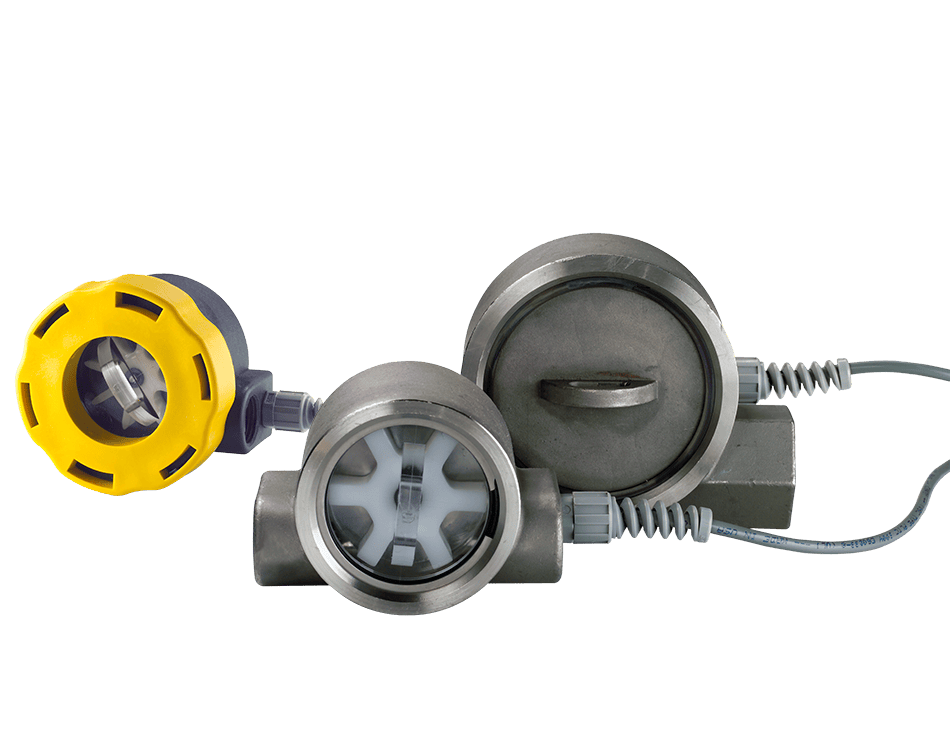

The Flow Rate Alarm is a rugged “flow switch” device that monitors flow and sends a signal using simple on/off logic if rates are out of spec. The weather tight NEMA 4x cast aluminum enclosure allows for outdoor installation and washdowns. Alarm settings are easily adjusted in the field with an allen wrench. The standard Hirschman interconnection provides easy installation and maintenance.

Applications include:

- Cooling systems

- Lubrication systems

- Mobile hydraulic equipment

- Industrial process control systems

- Technical Specs

- Non-wetted Components Materials

- Wetted Components Materials

- Dimensions

- Benefits

- Quick Ship

Manufacturer Name |

N/A AW-Lake Company |

Motion Item Number |

N/A 02959148 |

MINO |

N/A 05596J05975 |

UOM |

N/A EA |

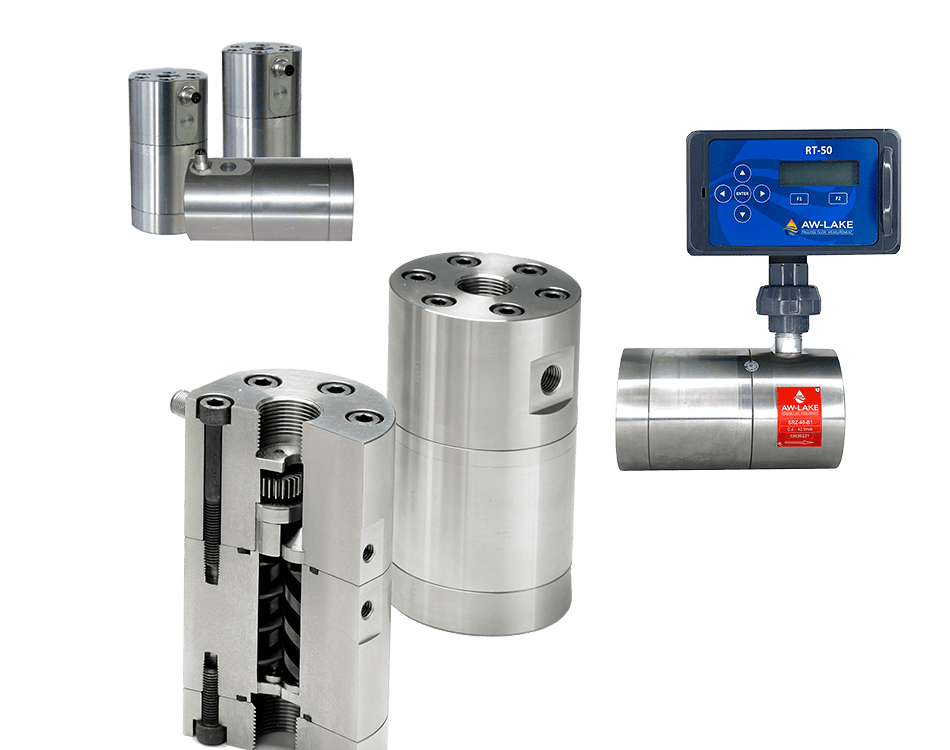

Type |

N/A Flow Rate Alarm |

Meter Style |

N/A 1 Switch |

Port Size Range |

N/A 1/4" - 1/2" |

Material |

N/A Aluminum |

Operating Pressure [Max] |

N/A 40 bar600 psi |

Fluid Media |

N/A Air & Gases |

Porting/Thread Type |

N/A #8 SAE, O-ring seal |

Flow Range - Air |

N/A 4 to 23 scfm |

Optional Flow Direction |

N/A Standard Flow, Uni-Directional |

Measuring Accuracy |

N/A ±2.0% of Full Scale |

Repeatability |

N/A ±1% of full scale |

Flow Measuring Range |

N/A 0.1 to 150 gpm0.5 to 550 L/min1 to 600 slps2 to 1300 scfm |

Operating Temperature [Max] |

N/A 185 ºF85 ºC |

Standard Calibration Fluids |

N/A Air meters: air at 70°F (21°C), 1.0 sg and 100 PSIG (6.8 Bar) Oil meters: DTE 25® at 110°F (43°C), 0.873 sg Water meters: tap water at 70°F (21°C), 1.0 sg |

Alarm Switch Dead-band |

N/A 4% of full scale |

Alarm Switch Contacts |

N/A SPDT (dry contact). 10 amps and 1/4 hp, 125 or 250 VAC. 1/2 amp, 125 VDC (regulated); 1/4 amp, 250 VDC (regulated); 3 amps, 125 VAC “L” (lamp load) |

Filtration Requirements |

N/A 74 micron filter or 200 mesh screen minimum |

Viscosity |

N/A Standard viscosities up to 110 cSt. For viscosities between 110 to 430 cSt contact factory. |

Process Port Type |

N/A #8 SAE |

Enclosure & Cover Material |

N/A Painted Aluminum |

Seals Material |

N/A Buna-N® |

Window Material |

N/A Pyrex® |

Din Connector Material |

N/A Polyamide |

Casing & End Ports Material |

N/A Anodized Aluminum |

Seals Material |

N/A Buna-N (STD), EPR, FKM or Kalrez® |

Transfer Magnet Material |

N/A PTFE coated Alnico |

All Other Internal Parts Material |

N/A Stainless Steel |

A |

N/A 6-9/16 in167 mm |

B |

N/A 2-3/16 in56 mm |

C |

N/A 4 in101 mm |

D |

N/A 1-7/8 in47 mm |

E |

N/A 4-7/8 in128 mm |

F |

N/A 2-1/4 in57 mm |

|

N/A

Field Adjustable Alarm Setting Weather-Tight Construction Simple On/Off Logic Pre-Wired with Cable Disconnect Economical Protection |

Quantity Available |

N/A {Unknown} |

*1-5 Pieces |

N/A {Unknown} |

*6-10 Pieces |

N/A {Unknown} |

Std Lead Time |

N/A {Unknown} |