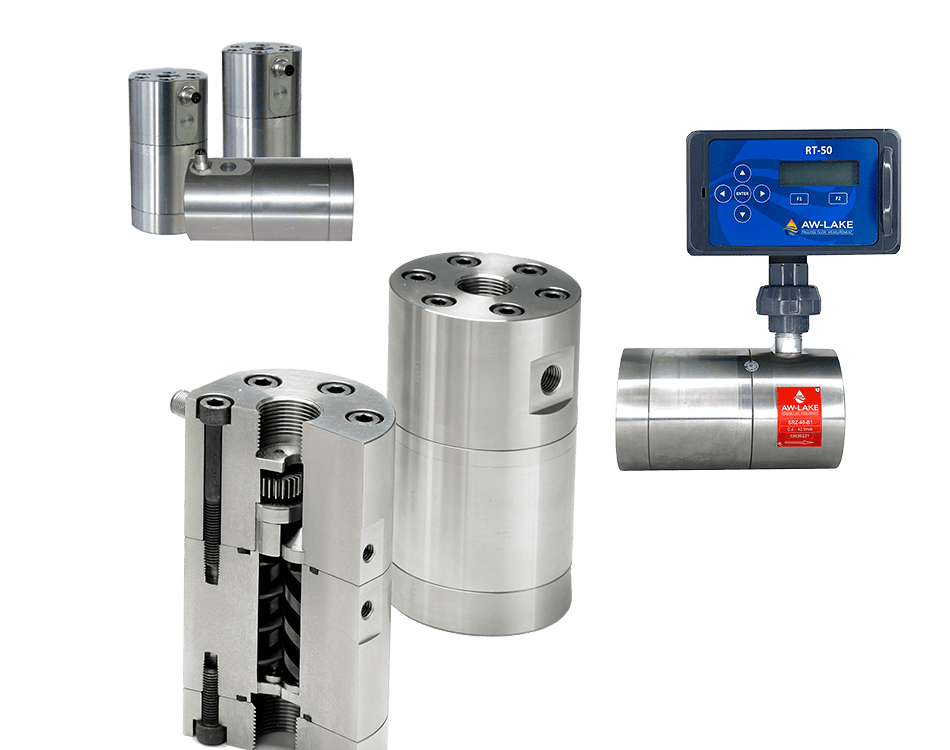

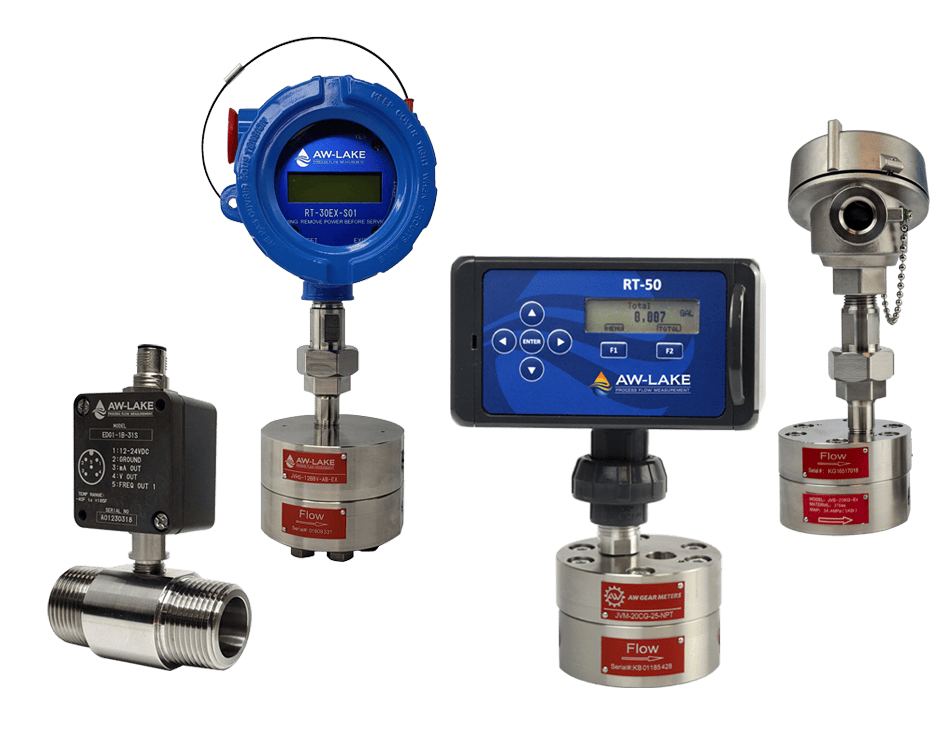

The SLG Compact Positive Displacement Spur Gear Meter is designed for measuring paints & coatings such as are found in the automotive industry. These stainless steel meters feature small, light bodies, perfect for installation on robotic arms and in other tight areas. Flow meter construction incorporates virtually no “dead space,” which allows for extremely efficient flush cycles and worry-free color changes.

- Rugged stainless steel construction performs under a variety of harsh, fast-paced conditions.

- Compact, light-weight meters are suitable where robotics is utilized or space is limited.

- Typical application is automotive paint lines.

Manufacturer Name |

N/A AW-Lake Company |

Measuring Accuracy |

N/A ± 0.5% over 10:1 turndown with 30cP fluid |

Repeatability |

N/A ± 0.1% |

Flow Measuring Range |

N/A 0.02 to 2.0 gpm |

Maximum Operating Pressure |

N/A 2000 psi |

Maximum Fluid Temperature |

N/A 350 ºF180 ºC |

Ports |

N/A 6 mm (not threaded) |

Resolution |

N/A 15900 pulses/gal4.2 pulses/cm³ |

Filtration |

N/A 120 µm |

Process Port Type |

N/A 6 MM NOT THREADED |

Weight |

N/A 3.0 lb1.36 kg |

Body Material |

N/A 316 stainless steel |

Gears Material |

N/A Stainless Steel, DIN 1.4122 |

Seal Material |

N/A PTFE O-ring |

Bearing Material |

N/A Tungsten Carbide |

Shaft Material |

N/A Tungsten Carbide |

|

N/A

In production environments like the automotive

industry, a lot of pressure is on line components.

While performing under a variety of harsh, fastpaced

conditions, flow meters in particular have

to be rugged, accurate, and easy to install. |

|

N/A

Strong, Compact Design Simple to Install & Use Accurate and Reliable Flexible |

Quantity Available |

N/A {Unknown} |

*1-5 Pieces |

N/A {Unknown} |

*6-10 Pieces |

N/A {Unknown} |

Std Lead Time |

N/A {Unknown} |